- Home

- Project overview

- Negative emissions

- Cambodia & Vietnam: Biochar-based fertilizers from rice husks

- Tanzania: Industrial production of biochar

- Nepal: biochar for the reutilisation of completely depleted soils

- India: Biochar from efficient cooking stoves

- Namibia: Industrial biochar production from encroaching bushes

- Kenya: Direct Air Capture

- Ghana: Distributed Biochar Production in Smallholder Farms

- Kenya: Direct Air Capture

Kenya: Direct Air Capture

atmosfair is sponsoring a module of the first Direct Air Capture plant in Africa.

Octavia Carbon, our project partner, is a Kenyan company, developing the technology locally.

The CO2 capture uses excess geothermal energy. The captured CO2 is then stored permanently underground.

Summary

| Total savings : | 15 tCO₂/year |

| Technology transfer : | Sponsoring a Direct Air Capture module using temperature-vacuum swing desorption technology. |

| Further advantages : | Development of the local Kenyan industrial facilities and job creation. |

| Local partners : | Octavia Carbon |

atmosfair is partnering with Octavia Carbon, supporting the development of the first Direct Air Capture (DAC) facility in Africa.

Our support to Direct Air Capture development

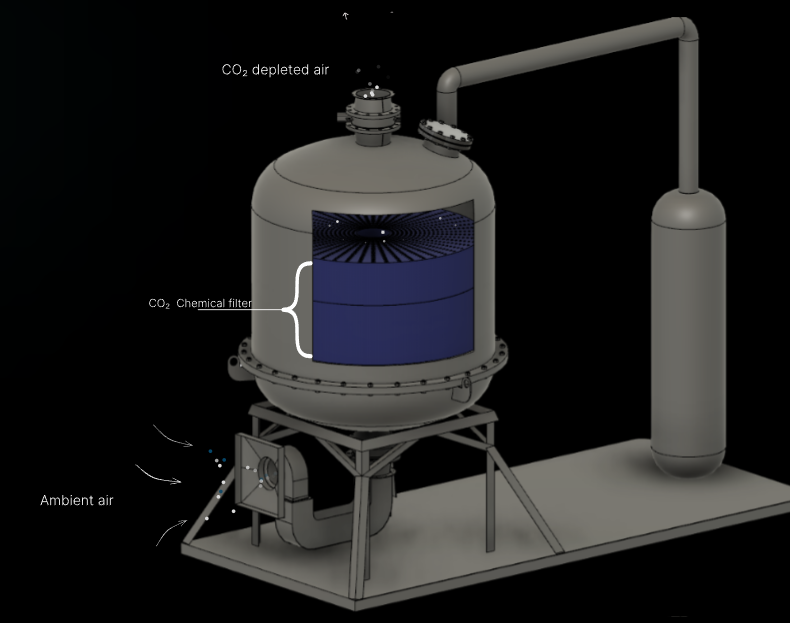

atmosfair is funding one unit of this plant. The DAC Unit is of the type “Nelion 1”, a 25tCO₂ /year DAC reactor, using geothermal energy for its energy consumption. The unit houses 4 DAC modules, cycled optimally for maximum capture in a 2-hour process, utilizing temperature-vacuum swing desorption. At a first stage, ambient air passes through the reactor while the filter captures CO₂. In the second stage, the system is sealed and heated under vacuum of 100mbar to initiate desorption at a temperature of around 90 to 100ºC.

The storage of CO2 is ensured through injecting it into reactive volcanic rock, where it dissolves and forms stable minerals, storing it in solid form for hundreds of years. The whole capturing and storage process is powered by surplus geothermal energy.

By sponsoring one of these units, atmosfair is supporting the development of a new world-class DAC facility, helping to prove DAC as an important carbon removal technology to be used towards solving climate change.

At this stage, the project is planned to deliver the removal of 15tCO2 per year, certified via Puro.Earth.

Direct Air Capture - The Technology

Direct Air Capture (DAC) is an innovative climate technology that aims to tackle global warming by directly removing carbon dioxide from the ambient air. The first concept of it was introduced in 1999, when Professor Klaus Lackner proposed removing CO₂ from the air at scale to combat climate change, building on earlier advances in chemical engineering and applications that trace back to air purification systems in submarines and space stations. By the 21st century, researchers and entrepreneurs began exploring DAC as a central piece in the portfolio of negative emissions technologies, pushing the boundaries of what was possible for climate action.

DAC is different to traditional carbon capture, which targets concentrated emissions in power plants or factories. Instead, DAC uses specialized chemical or physical processes to extract CO₂ from the the atmosphere itself. Two main technology options dominate the field today: solid sorbent systems, which capture CO₂ using specially designed filters, and liquid solvent systems, which rely on alkaline solutions to absorb carbon dioxide. After capture, the CO₂ is released from the media with energy, usually heat, purified, and then compressed for deep underground storage or use in products such as fuels or building materials.

The development of DAC has accelerated rapidly in the past decade. Leading companies, universities, and governments are now evaluating gigaton-scale deployment scenarios, aiming to drive down costs and energy demand to make DAC a viable solution for legacy emissions and hard-to-abate sectors. Costs remain high but the price is falling as the technology evolves, particularly for larger, more efficient facilities, and atmosfair hopes to accelerate this evolution by investing in this technology in the African continent.

One of the largest challenges for DAC is currently its energy-intensity, needing large amounts of clean energy to work. In answer to this, Octavia’s facility supported by atmosfair is using surplus geothermal energy.

Other challenges persist, including scaling up infrastructure and integrating DAC into carbon markets and climate policy frameworks. But the potential is great: DAC offers another pathway to “negative emissions,” and together with technologies such as biochar and ERW, may become a powerful tool against climate change.

Our Local Partner

Octavia Carbon has started the commissioning and operation of their Project Hummingbird, an innovative DAC and geological storage facility in Kenya’s Rift Valley. Octavia aims to scale up this plant to 1,500 tCO2 capacity by 2026, through 68 modular DAC Units, each averaging 25 tCO2/year. Octavia Carbon’s facility will create new jobs in the region, contributing to the knowledge transfer to Kenya and the country’s R&D efforts, as well as the concept-proof of DAC as a valuable technology.

Share

Share